Blog Credit: Trupti Thakur

Image Courtesy: Google

India’s First Green Hydrogen Plant

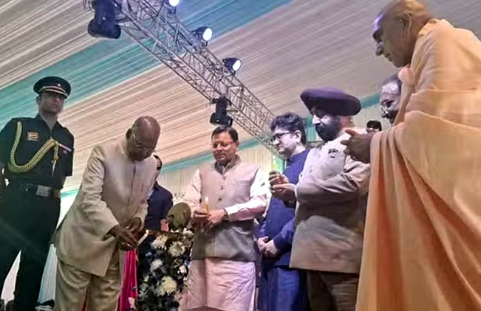

The first commercial-scale green hydrogen plant in India’s stainless steel sector was inaugurated on Monday (March 4) at Jindal Stainless Ltd’s (JSL) manufacturing unit in Haryana’s Hisar. The plant, which is expected to start with an initial production of 78 tonnes per year of green hydrogen, will be owned and operated by green hydrogen facilities developer Hygenco India for 20 years, after which the ownership and operations will be transferred to JSL.

The pact between JSL and Hygenco also marks the first-ever commercial long-term offtake agreement of green hydrogen in India, according to the two companies. To be sure, a few Indian companies, including Larsen & Toubro, Indian Oil corporation, Oil India, and NTPC, have built a few demonstration and pilot plants for green hydrogen production.

However, the green hydrogen being produced at those units is not being sold commercially and is mostly being used for application pilots and captive consumption to some extent. Various Indian energy companies, from the public sector as well as the private sector, have announced major plans to foray into the green hydrogen ecosystem.

The green hydrogen from the new JSL-Hygenco facility—which was inaugurated remotely by Steel Minister Jyotiraditya Scindia—is planned to replace the grey hydrogen produced from cracking of ammonia that is currently being used at the JSL manufacturing unit. Hydrogen is used in annealing of stainless steel, which is part of the heat treatment process. Under the agreement between JSL and Hygenco, high-purity green hydrogen will be supplied to the stainless steel manufacturer on a continuous basis under a 20-year fixed price offtake contract. The two companies did not share the project cost and the commercial details of the offtake agreement.

Green hydrogen refers to hydrogen produced from water electrolysis—splitting water into hydrogen and oxygen—by using renewable energy-powered electrolysers. It is considered a virtually emission-free pathway for hydrogen production. Currently, most of the hydrogen produced for industrial consumption and applications is grey hydrogen, which is produced from natural gas through energy-intensive processes and has high carbon emissions. Hydrogen currently is consumed mostly by the industrial sector in India.

With the new green hydrogen unit, JSL targets to reduce carbon emissions by around 2,700 tonnes per year, or 54,000 tonnes over 20 years. According to the company, its demand for pure hydrogen for annealing is around 353 tonnes per year, of which almost 72 tonnes per year is designed to be met through this green hydrogen facility.

Green hydrogen use and manufacturing in India is among the key thrust areas in the government’s overall vision for the country’s energy future and drastically cutting carbon emissions. In January 2023, the government launched the Rs 20,000-crore National Green Hydrogen Mission (NGHM) with the objective of turning India into a global hub for production, consumption, and export of green hydrogen and its derivatives.

The 2030 target for green hydrogen production capacity under the NGHM is 5 million tonnes per annum, contributing to reduction in dependence on import of fossil fuels. Achievement of the mission targets is expected to reduce India’s fossil fuel imports by a cumulative Rs 1 lakh crore by 2030.

Apart from major hydrogen-guzzling sectors like petroleum refining, India’s steel industry is counted among the sectors where green hydrogen use could grow exponentially over the coming years. Last month, the Ministry of New and Renewable Energy (MNRE)—the ministry responsible for implementing NGHM—issued guidelines for pilot projects for using green hydrogen in the steel sector, with a Rs 455-crore outlay till FY 2029-30.

“Three areas have been identified as thrust areas for the pilot projects in the steel sector. These are use of Hydrogen in direct reduced ironmaking (DRI) process; use of hydrogen in blast furnaces; and substitution of fossil fuels with green Hydrogen in a gradual manner. The scheme will also support pilot projects involving any other innovative use of hydrogen for reducing carbon emissions in iron and steel production,” the MNRE had said in a statement in February.

Green hydrogen, which is at a nascent stage globally, has a number of challenges as well, the foremost being the prohibitive cost of production, followed by challenges of storage and transportation at scale. However, with more innovation in technology and processes and scaling up of green hydrogen production, the costs are likely to come down, but that is likely to take a few years and considerable push from governments and the industry.

Blog By: Trupti Thakur

06

MarIndia’s First Green Hydrogen Plant

Mar 06, 2024Recent Blog

The ‘LignoSat’Nov 12, 2024

India’s First Writer’s VillageOct 28, 2024

The First Tri-Fold Of SamsungOct 24, 2024

India’s New Spam Tracking SystemOct 23, 2024

ICC T20 Women’s World Cup Winner 2024Oct 22, 2024